Case Study: Achieving significant nitrogen fertilizer optimization using Stenon’s FarmLab in collaboration with PepsiCo in potato production

Introduction

The amount of nitrogen fertilizer a farmer applies is one of the most critical factors influencing both costs and yields. Optimizing nitrogen fertilizer input is essential for achieving operational efficiency, promoting soil health, and reducing greenhouse gas emissions. Stenon, in collaboration with PepsiCo, conducted a study to demonstrate the effectiveness of the FarmLab in optimizing nitrogen usage.

The FarmLab was designed to provide growers with direct insights into soil nutrients and other critical parameters by delivering accurate, actionable, real-time data. To verify the potential nitrogen savings, Stenon and PepsiCo conducted comprehensive research studies.

Methodology

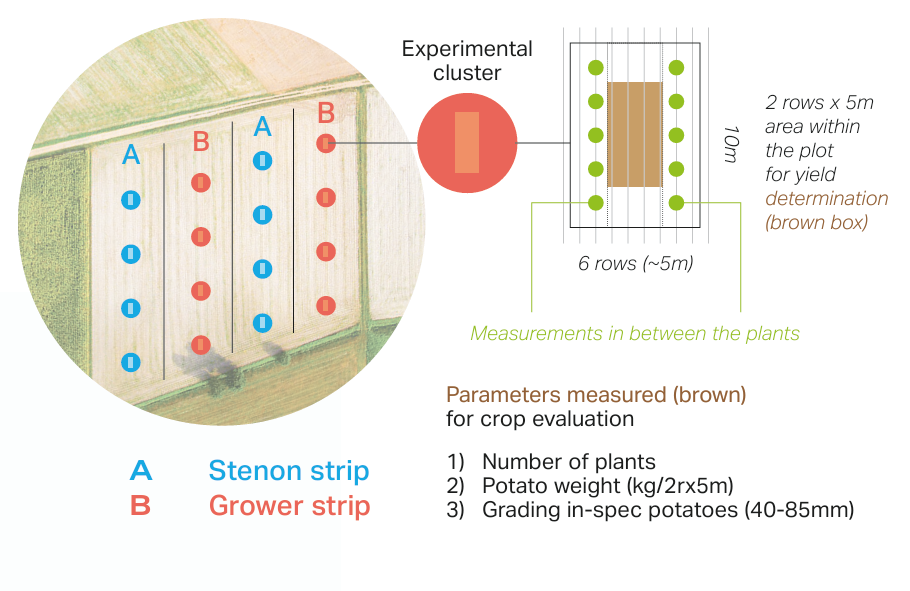

For this study, a split-field or strip design was employed, depending on the farmer's fertilization capabilities. In the strip-design approach, two Stenon-guided strips and two grower-guided strips were utilized.

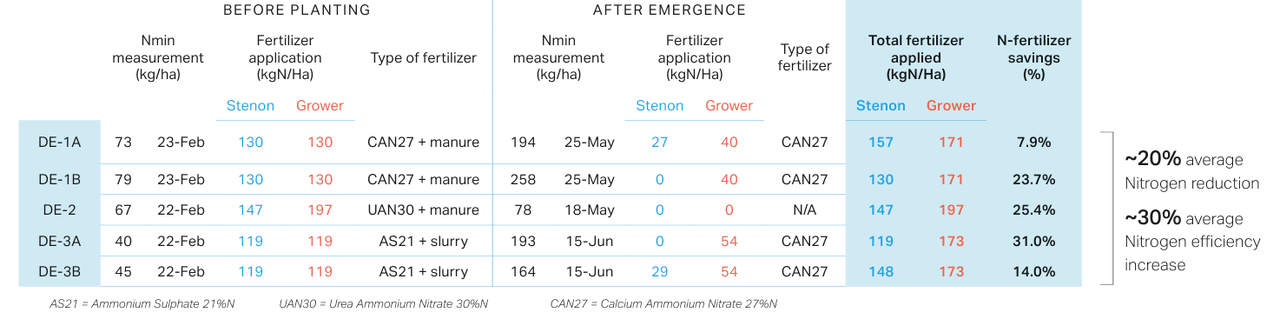

For the Stenon-guided strips, background mineral nitrogen (Nmin) levels were measured twice during the season using the FarmLab. The first measurement was taken before planting, and the second was taken before the second fertilization. These Nmin values were incorporated into fertilizer recommendations.

To evaluate yield, replicated yield digs were conducted across all strips. Potatoes were then sent to a laboratory for weighing, grading, and further analysis.

Stenon’s FarmLab

Stenon’s FarmLab utilizes Near-Infrared (NIR), UV-Vis, and Electrochemical Impedance Spectroscopy, integrating these technologies through a sensor fusion approach to provide real-time soil data. The device ensures high-quality data collection with built-in outlier detection. After the data is uploaded to the cloud, a machine learning algorithm processes the measurements and delivers nutrient values directly to growers via Stenon’s software.

Conclusion

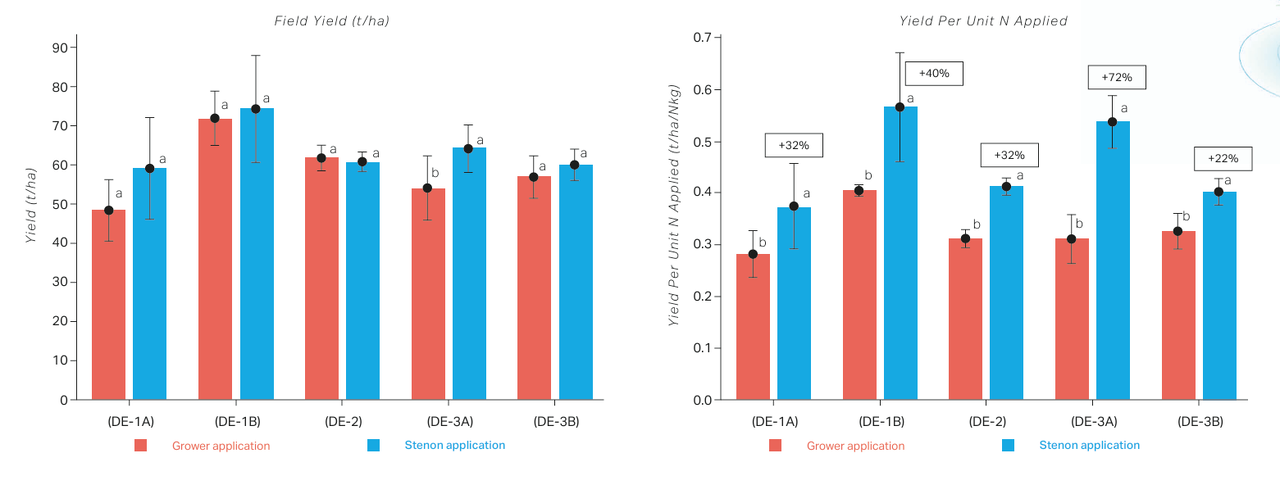

With real-time soil data from Stenon’s FarmLab, growers were able to significantly reduce nitrogen fertilizer inputs while maintaining yield parity and equal quality. The ability to access directly available mineral nitrogen data allowed growers to optimize their fertilizer applications efficiently.

A key advantage of using Stenon’s FarmLab compared to traditional laboratory analysis is the faster turnaround time—results are available in real time, whereas lab analysis typically requires several weeks. This efficiency enabled growers to save time and money, achieving an average cost reduction of over €100 per hectare. In some cases, savings exceeded this amount, as the second fertilizer application was rendered unnecessary.

Growers applying manure particularly benefited, as the warm growing season increased organic nitrogen mineralization. By monitoring nitrogen availability from both soil and manure, FarmLab provided additional value for growers using manure application as part of their nutrient management strategy.

Stenon’s collaboration with PepsiCo underscores the potential of cutting-edge technology to deliver both economic and environmental benefits in agriculture. This case study demonstrates the FarmLab’s ability to empower growers with data-driven insights, paving the way for more sustainable farming practices.